How much does a skid steer weigh? This question is crucial for anyone considering using these versatile machines for various tasks. Skid steers, known for their maneuverability and power, come in a range of sizes and configurations, each impacting their weight. Understanding the weight of a skid steer is essential for safe operation, transportation, and ensuring it’s suitable for the intended job.

From the compact models ideal for landscaping to the larger versions used in construction, the weight of a skid steer plays a significant role in its performance. Factors like engine size, attachments, and additional features all contribute to the overall weight, influencing its stability, maneuverability, and lifting capacity. This guide will delve into the intricacies of skid steer weight, exploring its impact on various aspects of operation and providing valuable insights for making informed decisions.

Skid Steer Weight Basics

Skid steers are versatile machines used in various industries, from construction to agriculture. Understanding their weight is crucial for safe operation and selecting the right model for specific tasks.

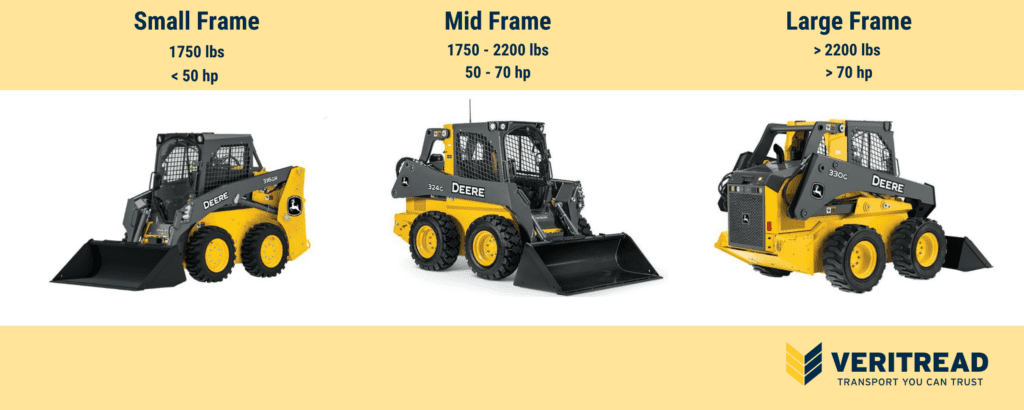

Average Weight Range

The average weight of a standard skid steer ranges from 3,000 to 10,000 pounds, depending on factors such as engine size, attachments, and features.

Factors Influencing Skid Steer Weight

Several factors contribute to the overall weight of a skid steer.

Engine Size

Larger engines provide more power but also increase the machine’s weight. A larger engine will typically weigh more than a smaller engine, and the weight of the engine contributes to the overall weight of the skid steer.

Attachments

Skid steers are designed to be compatible with various attachments, such as buckets, forks, and augers. The weight of these attachments can significantly impact the machine’s overall weight. For example, a heavy-duty bucket will weigh more than a standard bucket, and a hydraulic hammer will add considerable weight to the machine.

Features

Additional features, such as cab enclosures, air conditioning, and advanced hydraulic systems, can also increase the skid steer’s weight. These features add weight, but they also provide greater comfort, safety, and functionality.

Weight Comparison of Popular Models

The following table compares the weights of different skid steer models from popular manufacturers:

| Model | Manufacturer | Weight (lbs) |

|---|---|---|

| Bobcat S130 | Bobcat | 5,200 |

| Case SR175 | Case | 6,400 |

| John Deere 320G | John Deere | 6,700 |

| Kubota SVL95-2 | Kubota | 7,100 |

Importance of Skid Steer Weight

Skid steer weight is a crucial factor that significantly influences their performance, stability, and overall effectiveness. It’s not just about the total weight; how the weight is distributed and balanced also plays a critical role. Understanding the impact of weight on skid steers can help operators choose the right machine for their specific tasks and ensure safe and efficient operation.

Impact of Weight on Stability and Maneuverability

Skid steer weight directly impacts their stability and maneuverability. A heavier skid steer generally provides better stability, especially when working on uneven terrain or slopes. The added weight acts as ballast, lowering the center of gravity and reducing the risk of tipping over. However, excessive weight can make the skid steer less maneuverable, especially in tight spaces or when turning. The ideal weight for stability and maneuverability depends on the specific application and working conditions.

Impact of Weight on Lifting Capacity and Overall Performance

The weight of a skid steer directly influences its lifting capacity. Heavier skid steers typically have higher lifting capacities because they provide a more stable base for lifting heavy loads. This increased lifting capacity allows operators to handle larger and heavier materials, improving efficiency and productivity. However, heavier skid steers require more powerful engines to operate, which can increase fuel consumption and operating costs.

Impact of Weight Distribution on Attachment Effectiveness

The distribution of weight in a skid steer significantly affects the effectiveness of different attachments. For example, a skid steer with a heavy front end might be better suited for tasks like digging or pushing, as the added weight provides more force. However, a skid steer with a more balanced weight distribution might be better suited for tasks like lifting or loading, as it provides better stability and control. The ideal weight distribution depends on the specific attachment and the task at hand.

Understanding Weight Distribution: How Much Does A Skid Steer Weigh

A skid steer’s weight is not evenly distributed across its chassis. It’s concentrated towards the front, particularly in the area of the engine and the lift arms. This uneven distribution is intentional and plays a crucial role in the machine’s performance and stability.

Weight Distribution Impact on Skid Steer Stability and Performance

The distribution of weight in a skid steer is crucial for its stability and maneuverability. A balanced weight distribution ensures the machine remains stable during operation, especially when lifting heavy loads or navigating uneven terrain.

A well-balanced skid steer will have a lower center of gravity, improving its stability and reducing the risk of tipping over.

- Enhanced Stability: Balanced weight distribution lowers the center of gravity, improving the machine’s stability, especially when lifting heavy loads or working on inclines. A lower center of gravity makes it less likely for the skid steer to tip over, enhancing operator safety and productivity.

- Improved Maneuverability: Proper weight distribution allows for smooth and controlled turning, even when operating on uneven terrain. It ensures the skid steer responds quickly and accurately to operator inputs, enabling efficient and precise maneuvering.

Uneven Weight Distribution and its Impact on Skid Steer Handling, How much does a skid steer weigh

Uneven weight distribution can negatively impact a skid steer’s handling and maneuverability.

- Increased Risk of Tipping: When weight is disproportionately distributed, the center of gravity shifts, making the machine more susceptible to tipping over, especially when operating on inclines or lifting heavy loads.

- Reduced Maneuverability: Uneven weight distribution can make the skid steer difficult to control, especially when turning or maneuvering on uneven terrain. This can lead to decreased efficiency and increased risk of accidents.

- Excessive Wear and Tear: Uneven weight distribution can place excessive stress on certain components, leading to premature wear and tear, requiring more frequent maintenance and repairs.

Weight Considerations for Transport and Storage

The weight of a skid steer is a crucial factor to consider when transporting and storing it. It impacts the type of trailer needed, the loading capacity of the area, and even the logistics of moving it. Understanding how weight affects these aspects is essential for safe and efficient handling.

Trailer Requirements and Weight Limits

The weight of a skid steer directly influences the type of trailer required for transport. It’s essential to choose a trailer that can safely handle the skid steer’s weight and any additional cargo. Exceeding the trailer’s weight limit can lead to serious consequences, including accidents, damage to the trailer, and legal repercussions.

- Trailer Capacity: Trailers come in various sizes and weight capacities. The capacity of the trailer must be greater than or equal to the combined weight of the skid steer, any additional cargo, and the trailer itself. It’s crucial to consult the trailer’s specifications for its weight capacity and ensure it aligns with the skid steer’s weight.

- Trailer Type: Different types of trailers are designed for different purposes and weights. For example, a flatbed trailer is suitable for heavier loads, while a utility trailer is more appropriate for lighter equipment. The type of trailer chosen should be compatible with the weight of the skid steer and the intended use.

- Braking System: The weight of the skid steer can impact the braking system of the trailer. Heavier loads require more robust braking systems to ensure safe stopping. It’s essential to consider the trailer’s braking system capacity when transporting a skid steer.

Weight Impact on Transportation Costs and Logistics

The weight of a skid steer can significantly influence transportation costs and logistical planning. Heavier skid steers require larger trucks and trailers, which translates to higher fuel consumption and transportation fees.

- Fuel Consumption: Heavier vehicles consume more fuel, leading to increased transportation costs. This is especially relevant for long-distance transport.

- Truck and Trailer Size: Heavier skid steers require larger trucks and trailers, which may be subject to different regulations and restrictions. These factors can impact the logistics of transportation, including route planning and delivery schedules.

- Specialized Transport: In some cases, very heavy skid steers may require specialized transport equipment, such as low-bed trailers or heavy-duty haulers. These specialized services can significantly increase transportation costs.

Storage Area Considerations

The weight of a skid steer also influences storage requirements. Storage areas must be able to support the skid steer’s weight without compromising structural integrity.

- Floor Capacity: The floor of the storage area must be strong enough to support the weight of the skid steer. Weak floors can lead to damage and instability, posing a safety hazard.

- Support Structures: If the skid steer is stored on elevated platforms or racks, the supporting structures must be able to handle the weight. Regular inspections and maintenance of these structures are essential to ensure safety.

- Access and Maneuverability: The storage area should be designed to allow for easy access and maneuverability of the skid steer. This is particularly important if the skid steer needs to be moved frequently.

Final Summary

Knowing the weight of a skid steer is paramount for ensuring its safe and efficient operation. By understanding the factors that influence weight, considering its impact on performance, and carefully planning for transportation and storage, you can maximize the benefits of this powerful machine. Whether you’re a seasoned operator or a newcomer to the world of skid steers, a comprehensive understanding of weight considerations is essential for success in various applications.

General Inquiries

What is the average weight of a skid steer?

The average weight of a skid steer can vary significantly depending on the model, engine size, and attachments. Generally, they range from around 3,000 to 10,000 pounds.

How does weight affect skid steer maneuverability?

Heavier skid steers may have slightly reduced maneuverability, especially in tight spaces. However, they offer greater stability and traction on uneven terrain.

Can I find the weight of a specific skid steer model online?

Yes, most manufacturers provide detailed specifications, including weight, on their websites or in brochures.

How can I calculate the weight of a skid steer with attachments?

Add the weight of the attachments to the base weight of the skid steer. This will give you a more accurate estimate of the total weight.